Backward and Forward Delivery Scheduling

This page is intended to explain the types of scheduling in Sales and Delivery. Scheduling is carried out in two ways. This document explains when scheduling is run and the type that is run.

When a sales order is created, the system determines the required material availability date on the basis of the customer’s requested delivery date. This date is based on times used for picking, packing, labelling, and loading the goods. Therefore, this is the date of significance for requirements planning on which the availability should be checked.

Types of Scheduling

The Scheduling is separated into steps:

- Scheduling at the shipping point (shipping scheduling)

- Scheduling of the transport (transport scheduling)

These types should be activated in transaction OVLY for sales document type .It is also necessary to maintain calendars for Shipping Point (Transaction SPRO), Route (found via departure zone, countries, shipping conditions, transport group, weight group (Transaction SM31 TVRO) and Unloading Point (Transaction VD02). Without a valid calendar, scheduling is not possible.

Times to be maintained

SPRO: IMG -> Logistics Execution -> Shipping -> Basic Shipping Functions -> Scheduling -> Delivery Scheduling and Transportation Scheduling -> Maintain Duration

- Shipping Point (Factory calendar, Working times)

- Pick/pack time (shipping point – route, SM30, T630R)

- Loading time (shipping point – route – loading group, SM30, T630L)

- Transit time (route, SM31, TVRO)

- Lead time for transport planning (optional) (route, SM31, TVRO)

- Working Hours (or calendar) for Unloading Point (VD02)

How it works

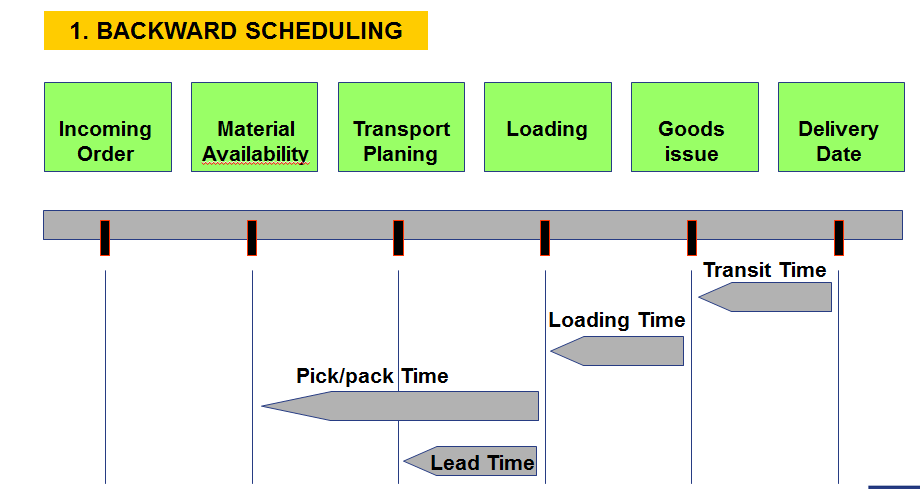

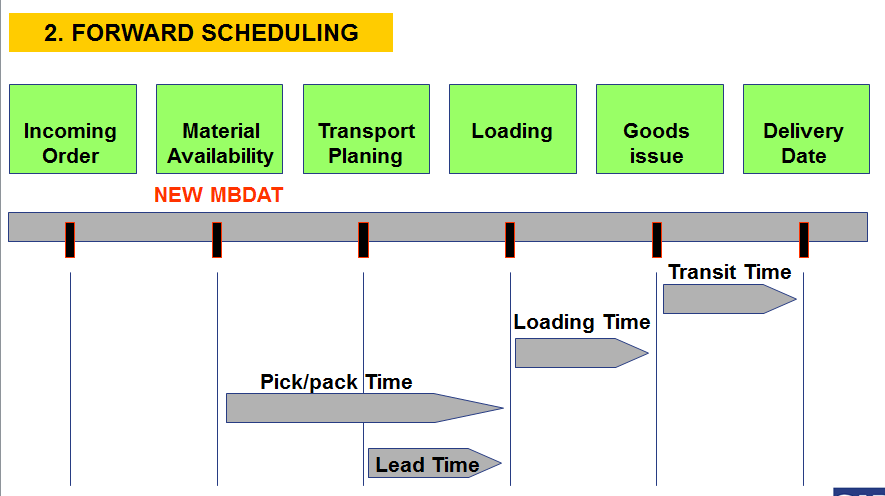

Scheduling works in two ways backward and forward Scheduling. When you create an Item, the system carries out delivery scheduling backward. If the material availability date lies in the past, the system performs then performs a forward scheduling.

Requested delivery Date -> Material availability date